We’re committed to eradicating all traces of palm oil from our supply chain

With more palm-free materials on the horizon, we’re making steady progress…

Together with the climate emergency, biodiversity loss is one of the big pressing issues of our times. The evolution of life moves towards more diversity and complexity. We know, for example, that increasing plant species diversity contributes to increased ecosystem services. How can we, as humanity and as a business, contribute to ensure our biodiversity keeps flourishing?

The current estimates is that of all mammals on the face of the Earth, only 4% represent all the different species of wild mammals, 36% are humans and 60% domesticated animals, mainly livestock. When it comes to birds, 70% are poultry and only 30% are wild free birds. When it comes to agriculture, only 9 plant species contribute to 66% of all crop production.

We are in the business of making cosmetics that use lots of different natural raw materials, so our business relies on a thriving community of life. We affect biodiversity in the types of materials we choose, how they are grown and sourced, how much waste and pollution our business generates and our contribution to larger factors like climate change and land degradation. Our long-term commitment is to ensure our business positively contributes to abundant, diverse and lush life on the planet. This is trickier to deliver than it sounds, and hard to measure.

It starts by understanding better the pressures on natural habitats in our supply chain, working to reduce those pressures while continuing to develop and support projects clearly demonstrating that raw materials supply and biodiversity can go hand in hand. Our products effectiveness also rely on careful formulations using over 800 different natural raw materials, essential oils and safe synthetics from 317 different species, adding to a growing richness and variety in our supply chain.

With more palm-free materials on the horizon, we’re making steady progress…

For all our careers (extending nearly 45 years) in the formulation of our products, we have looked to solve the environmental issues that can arise from their sourcing, manufacture, retailing and use. So that our customers can enjoy their Lush products knowing that they have been invented with thought and care for the environment.

We are working, always, to improve the environmental impact of our products and this means looking at several issues at once. Naked, plastic free, self preserving and palm free products are all aspects we are developing and achieving. But we have to remember that our customers expect viable products that work for them. No matter how ‘green’ a product – if it doesn’t work for the customer, they won’t buy it again. They expect a good effect and we work to provide that.

We have been working on palm free product formulations for many years. Many of our products are palm free but we are not in a position at the moment to declare ‘ranges’ of products are palm free. We don’t use palm/ palm kernel oil as an ingredient. But, some of the ingredients we buy to use in our products, such as shampoo bases, are not palm free and can be mixed with other oils like coconut. The base ingredients of these blends cannot be guaranteed. So no palm is the only guarantee. We cannot rely on the sources of sustainable palm to be traceable enough.

We have looked at the palm based ingredients that we buy and considered if we could manufacture them ourselves. For example we looked at shampoo bases (the largest volume used) as we make our own soap. Shampoo bases are from the same sources and the chemistry and the process of making them are several steps along the way from soap manufacture. But these several steps involve boiling acids and incredibly high temperatures and we cannot do that.

So it comes down to formulation with ingredients we can source, considering our policy on animal testing and our own innovation and invention. We need manufacturers and suppliers to work with us on this but it isn’t always possible.

Though Lush is quite a large company, it is still small on a global scale and our buying power is not always powerful enough. But some manufacturers are willing to work with us and we really appreciate their support. This can lead to the development of new ingredients for them, for example soap flakes, which are non animal, non palm, which they can sell to other sources.

We have made good progress in shampoo bases and this is the largest area in which palm is in the base ingredients we use. Lush buys the most here, in terms of bulk and expenditure. We are currently looking at emulsions for our creams.

This requires careful work as these are products which successfully care for sensitive, delicate skin and are life long favourites of many thousands of our customers. We have to get this right.

Lush is progressing on so many environmental aspects but there is work to do to solve the environmental issues like palm production that are so damaging to our planet. Changes we can make have to deliver the products our customers know and love but with the knowledge and transparency to reassure them that they can use their products with as little environmental impact as can possibly be.

At the core of our buying strategy is the constant drive to reduce the negative impacts of our supply chain and enhance the positive ones. By analysing our ingredients to understand how they contribute to global issues, we are able to proactively work on improving the supply chain.

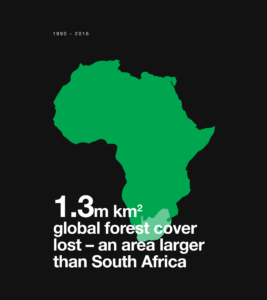

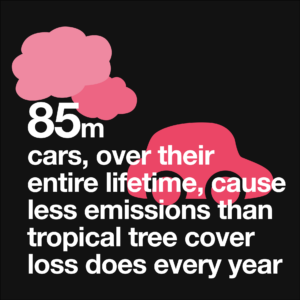

Deforestation is a leading cause of climate change. The leading cause of deforestation is agriculture through the extraction of timber for furniture and paper, livestock farming, and the cultivation of soya and palm oil. To ensure that we are not contributing to this issue, we must investigate our supply chain for risk indicators – such an indicator is the use of palm oil.

Since 2006, Lush has been working to remove palm oil and palm kernel oil from the supply chain. Progress has been made, and we are sourcing ingredients derived from a far bigger variety of oil feedstocks. This has allowed us to produce a large number of products that are completely palm free.

This report will explore the changes that have been made, give a broad overview of the palm debate and will compare the impacts of each of the vegetable oil feedstocks (palm, olive, coconut, rapeseed) so that we have a better understanding of the impact of switching.

Palm oil is by far the most important source of vegetable oil in the world. The oil is derived from the fruits of the Elaeis Guineensis palm. Each fruit consists of a hard kernel within a shell (endocarp) which in turn is surrounded by a fleshy mesocarp. Two chemically distinct oils can be obtained from the fruit. The first is what we know as palm oil and it is derived from the fleshy mesocarp, the second is palm kernel oil which comes from the inner seed. These oils are incredibly versatile with a wide range of uses; 71% of palm oil is used by the food and beverage industry, 24% in cosmetics, the remaining 5% for biofuels, animal feed and much more.

The Oil Palm originated in the tropical rain forest region of West Africa. As an ornamental tree, it was taken across the globe until it reached South-east Asia, where it flourished, becoming the largest commercial production of a crop far removed from its origin. Now 85% of Palm is produced in Indonesia and Malaysia, 42 other countries produce the remaining 15%. The graph below shows the incredibly rapid growth of global palm production.

Palm oil is just one of the many vegetable oils produced globally; the demand for these is huge and will only keep growing. Between 2018 and 2019, approximately 203 million metric tonnes were produced globally, this is expected to reach 307 million metric tonnes by 2050.

The Oleochemical Industry

Vegetables oils have many uses in cosmetics; in their unprocessed form they provide texture and moisture, but more importantly they are the feedstock to many cosmetic ingredients. The oils can be broken down into their individual components such as glycerol, fatty acids and fatty alcohols. These derivatives are then used in products for their emollient or foaming properties. The industrial processing of derivatives involves a wide range of stakeholders leading to long and ramified supply chains, much more complex than the ones concerning unprocessed oil. This complexity stems from the fact that between the plantations and the ingredients used in products, there are many transformations and intermediaries: millers, crushers, grinders, refiners, fractioners, traders and oleo-chemicals manufacturers.

On paper, the oil palm looks to be the perfect crop – a long economic lifespan, high yielding and produces two nutritious and highly versatile oils. However the palm requires high rates of rainfall between 1600mm and 5000mm and high temperatures, this has limited its range to some of the most biodiverse regions of the planet. As a result of its expansion in these areas, it has been a major driver of deforestation and peatland conversion. The destruction of tropical forests and peatlands, often using fire, is a major contributor to climate change, biodiversity loss, soil erosion, water pollution, invasive species; as well as human rights abuses.

Palm oil threats:

In 2015, haze from land-clearance fires in Indonesia led to 500,000 reported cases of respiratory illnesses and 19 people died.

Whilst the environmental impacts are staggering, the largest conservation organisations in the world, the WWF and IUCN, both argue that a shift away from Palm will simply spread the impacts over a larger area of land as the oil yields are far lower for other oil crops. They instead argue that the industry must demand sustainable palm cultivation, with the only recognised certification body being the RSPO. However only 19% of all the palm oil produced is from certified sources.

The RSPO was setup in 2004 as a reaction to the increased scrutiny of the palm sector; it has become the world’s most widely used voluntary certification scheme for palm oil.. The ultimate aim is to make sustainable production the norm which comprises legal, economically viable, environmentally appropriate and socially beneficial management and operations. This is delivered through the application of the following set of goals and principles, along with the accompanying Indicators and Guidance.

Whilst the RSPO represents an important force in the oil palm industry, it isn’t without criticism. The Environmental Investigation Agency’s second report on the RSPO, called them out for “greenwashing” by giving false environmental credibility to certified products. They argue that the standard isn’t enforced sufficiently, and that there is fraudulent auditing of plantations, that primary forests are still being felled and community land rights are still being violated. These criticisms are echoed by many other NGOs.

Furthermore there is a lack of commitment by members to produce certified palm which is clear when considering the number of members and comparatively low volumes of certified palm oil. Furthermore there is no current requirement for non-grower members such as consumer goods manufacturers, processors/traders and retailers to buy any certified palm oil at all. It is clear that whilst the RSPO has bold ambitions, the implementation of the standard falls short of them; creating a facade over the industry.

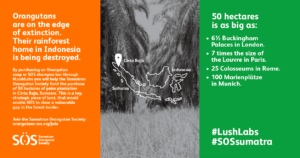

In northern Sumatra, biodiversity is returning to a once decimated area of a World Heritage forest. The Gunung Leuser National Park of the Leuser Ecosystem is recognised as one of the most important forest areas in the world, yet is threatened by palm plantations, illegal logging, and hunting. Since 2017, some 100 hectares of oil palm plantation directly adjacent to the park have been transformed as a result of two campaigns by the Sumatran conservation group the Orangutan Information Centre and the Sumatran Orangutan Society, and supported by Lush.

However its derivatives is used in some of our surfactants and emulsifiers.

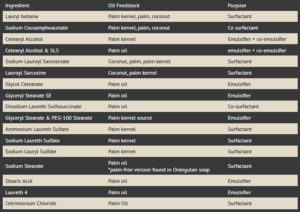

Lush does not purchase any palm oil or palm kernel oil, however its derivatives is used in some of our surfactants and emulsifiers. Whilst we have been able to work with suppliers to source replacements for some of these materials; for others, the incredibly complex value chain has meant that it is next to impossible to source the exact ingredient without any palm. This is because the surfactant industry is built around using palm; and similar to the petrochemical industry, the processes only become economical on massive scales; therefore smaller manufacturers who might want to produce the same ingredients without palm are unable to do so – thus it all boils down to complete re-formulation & restructuring of our products.

Below is a table of all the palm derived materials and their uses.

By working with suppliers to diversify the feedstocks used in our synthetics, we will be putting less pressure on one ecosystem, and reduce the overall risk of deforestation and land degradation. Additionally we hope to gain more traceability and more control over the types of oils used and how they have been grown. This has been a long and complicated journey.

The latest developments see the 2020 Spring products showcase a range of products that contain a diversity of feedstocks, not including palm. This will be the test bed to see if our customers like the feel of the products that contain new ingredients. We’re putting them to the test.

Diversification of our Soap

First attempts to remove palm oil from products began with a change of our soap base to a palm free formulation. This involved making our own bases to trial in products and then taking our request for a palm free base to external soap base manufacturers.

The original formulation was a mix of hydrogenated rapeseed oil, sunflower oil and coconut fat. But this was superseded by another manufacturer’s base that was developed a little later and made from hydrogenated rapeseed oil and coconut fat. Palm free soap base became a reality in 2007.

Since then we have also removed sodium lauryl sulfate and sodium stearate (or substituted with PF sodium stearate) from almost all our soaps. The soap range was completely palm free for a short while but we’ve recently had to add the SLS back to Fresh Farmacy to stabilise the product.

We have also introduced a series of in-house soap bases made with 13 different oils and directly supporting thousands of farmers in 6 grower cooperatives. Removing the palm oil has benefitted the soap range by introducing more variety of materials, textures and effects in the finished products. There is now a collection of bases that we can mix and match rather than relying on the same base for every soap.

As a user of an end product, Lush is reliant on distributors and manufacturers for the materials. We are therefore a number of steps removed from the primary cultivation of the palm and the main negative impacts. As most manufacturers purchase processed oils, fatty acids and amines to produce surfactants, they are also removed from the primary source of oil. In order to ensure that we are not supporting deforestation, it is essential that we develop transparency and traceability throughout the supply chain by working with our suppliers. This has been a part of our buying strategy since the beginning; however in 2018 and 2019 we took significant steps to improve our chances of success.

The Future

Whilst we continue to look at new alternative materials to switch over to, as they are manufactured, we have decided to move towards developing a bigger picture solution to shape the whole industry surrounding palm derived synthetics. This is the only real way Lush will be able to go palm free. We believe we have the beginnings of a solution but we will need the collaboration of other companies and investment in order to provide a range of palm free synthetics that will work in our products and that are not tested on animals. We believe this is where we can make real, global change towards preventing further deforestation.

Challenges In order to create the change that is needed, we have to overcome some large challenges:

Solutions

In order to overcome these, we must form a larger group of companies with a shared purpose of developing the adequate volumes of ingredients that do not contribute to deforestation and biodiversity loss.

12:11